| Device name: | Ultrafine powder spray dryer |

| Equipment type: | qfn - cx - 3 |

| Equipment specifications: | 3Kg/h (support customized) |

| Test machine: | Support test making experiment |

| Scope of application: | Powdered and granular solid products are produced in solution, emulsion, suspension and paste liquid raw materials. |

| Application scenario: | Scientific research, chemical industry, food, pesticide, medicine, biological industry, etc. |

| Is it guaranteed? | National three year warranty |

| Telephone: | 17317246351 |

1. features of equipment:

2. Equipment advantage

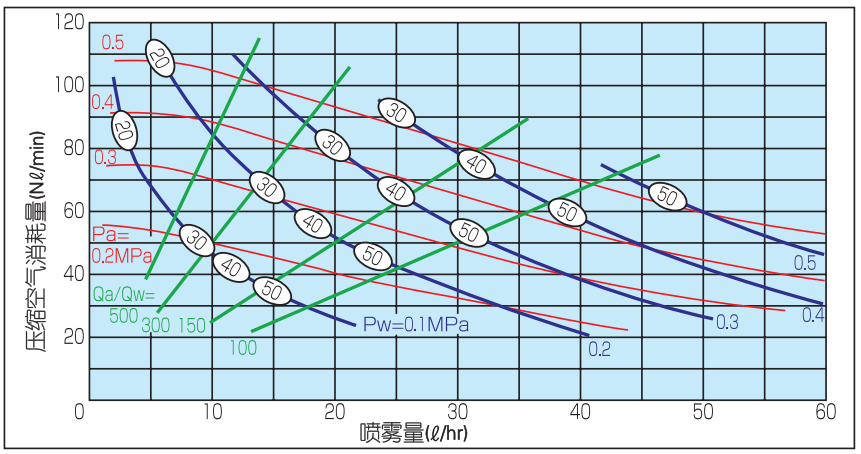

Two dimensional graph of 4.QFN-PWCX-NZY8VER2018-075A atomization system

Line graph reading

1 is the spray amount of a nozzle (l/hr)

2 the red line represents compressed air PA (MPA), the blue line represents the liquid pressure, PW (MPA), and the green line represents the QA/QW vapor / water ratio.

3. the number in the figure shows that the two-dimensional curve of 4.QFN-PWCX-NZY8VER2018-075A type atomization system is determined by

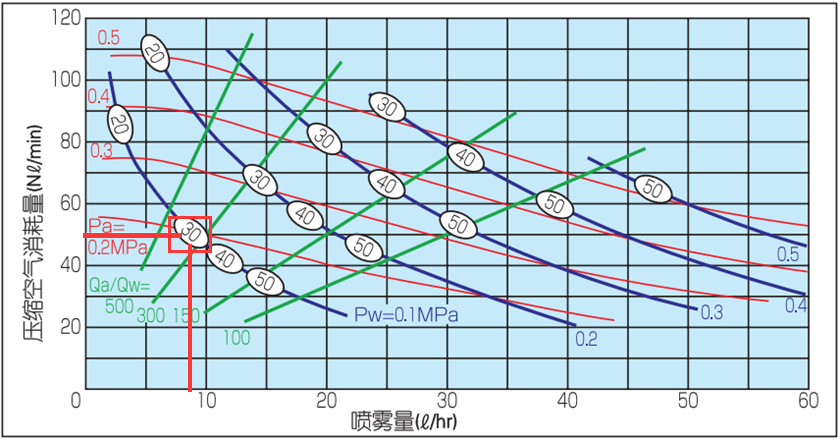

Line graph reading

1 is the spray amount of a nozzle (l/hr)

2 the red line represents compressed air PA (MPA), the blue line represents the liquid pressure, PW (MPA), and the green line represents the QA/QW vapor / water ratio.

3.  The numbers inside represent the average particle size (micron) of SAUTER measured by the detector.

The numbers inside represent the average particle size (micron) of SAUTER measured by the detector.

Type QFN-CX-NZY8VER2018-075A atomization system:

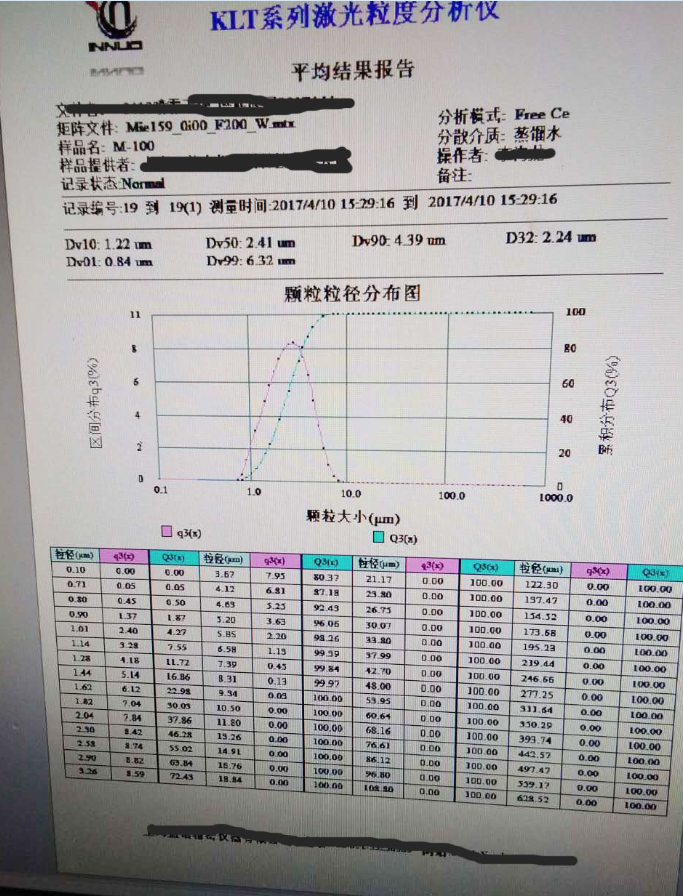

For example, if the final average dry powder particle diameter is about 3 microns, the known condition is that the solid content of the feed solution is 10%.

The required average wet droplet size is 3/0.1=30 microns. The liquid intake is about 8L/hr, compressed air needs 0.2MPA, and the intersection point is about 30 microns.

If need other size diameter of droplets, first determine the amount of processing, a vertical axis, find the approximate size, and then find the point of intersection, find the pressure of compressed air.

Note: according to the density of material, viscosity and other parameters, the average diameter of droplet should be 30 + 3, [-27,33], 3.

5.Equipment configuration

|

system |

number |

parts |

brand |

Model |

Number |

Remarks |

|

electric |

One |

Electronic control system of QFN-CX series atomizing dryer |

Maple Maple |

/ |

1 sets |

See device parameters |

|

Two |

Switching Mode Power Supply |

The Ming and Wei |

you - 100 - 24 |

The 1 |

/ |

|

|

Three |

Air switch |

chint |

DZ47 series |

Some |

/ |

|

|

Four |

Small relay |

chint |

JZX-22F (D) /2Z |

Some |

/ |

|

|

JZX-22F (D) /4Z |

||||||

|

Five |

Solid state relay |

Meg |

/ |

1 sets |

/ |

|

|

Six |

Frequency converter |

Taida |

/ |

1 sets |

2.2kw |

|

|

Seven |

Digital controller |

Taida |

DTC-1000 series |

Some |

/ |

|

|

Eight |

Power switch |

|

|

The 1 |

|

|

|

Nine |

Indicator light |

chint |

nd16 - 22ds / 4 |

The 1 |

Red, 220VAC |

|

|

Ten |

sensor |

Famous Shanghai |

wzp - 241 |

3 roots |

/ |

|

|

Eleven |

Terminal terminal |

/ |

/ |

Some |

/ |

|

|

Twelve |

Guide |

/ |

/ |

Some |

/ |

|

|

Thirteen |

Groove |

/ |

/ |

Some |

Bottom hole |

|

|

Fourteen |

wire |

Sails |

/ |

/ |

/ |

|

|

Fifteen |

Electric box |

Maple Maple |

Customized |

The 1 |

sus304 |

|

|

transport |

One |

Peristaltic pump |

Hui Yu |

yz15 13a |

1 sets |

/ |

|

Two |

Feed pipe |

/ |

|

/ |

/ |

|

|

Fog |

One |

Atomization system |

Maple Maple |

Customized |

1 sets |

See device parameters |

|

Two |

Pressure gauge |

AirTAC |

0-1MPA |

|

/ |

|

|

Three |

Circulating pump |

/ |

/ |

One |

/ |

|

|

Three |

Air compressor |

Dolphin |

0-0.8MPA |

1 sets |

/ |

|

|

dry |

One |

Dry pagoda |

Maple Maple |

/ |

The 1 |

See device parameters |

|

Two |

Hot air distributor and volute (matching of atomization system) |

Maple Maple |

Customized |

The 1 |

Three hundred and four |

|

|

yield |

One |

cyclone |

Maple Maple |

Customized |

One |

Three hundred and four |

|

Two |

Dust collector (optional) |

Maple Maple |

Customized |

/ |

See device parameters |

|

|

Three |

Collecting bucket |

Maple Maple |

Customized |

Three |

Three hundred and four |

|

|

Four |

Feed valve |

Warm letter |

φ63 / 108mm |

Three |

Health level 304 |

|

|

Hot air circulation system |

One |

Fan |

/ |

/ |

1 sets |

See device parameters |

|

Two |

heater |

Maple Maple |

Customized |

|

See device parameters |

6.Equipment parameters

|

Ultrafine powder spray dryer |

qfn -CX-3 |

qfn -CX-Five |

qfn -CX-Ten |

|

Water evaporation |

3Kg/h |

5Kg/h |

10Kg/h |

|

Minimum feed volume |

80ml |

80ml |

120ml |

|

The diameter of the drying chamber (mm) |

¢600 |

¢800 |

¢1200 |

|

Height of dry tower (mm) |

¢800 |

¢800 |

¢1500 |

|

Atomization structure |

Single hole eccentric atomizing structure (QFN-CX-NZY8VER2018-1A) |

||

|

Electronic control system |

Jo Feng superfine powder atomization system only (QFN-CX-ES-VER2018-1A) |

||

|

Maximum inlet temperature (centigrade) |

Two hundred and sixty |

||

|

Standard of main electrical accessories (including PLC, analog module, touch screen) (optional) |

Control module (standard), delta control module, SIEMENS control module, Germany. |

||

|

Standard of electrical auxiliary accessories selection (including Contactors) (optional) |

CHINT (standard): Deli, Schneider. |

||

|

Contact with the material (optional) |

?sus304 (標(biāo)準(zhǔn)) □sus316 □其他 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

||

|

Exhaust reutilization, energy saving over 30% (optional) |

Assembly (standard) / assembly |

||

|

Atomizing nozzle (using diamond coating) |

(SUS304) (standard) SUS316 (standard) silicon carbide (standard) diamond |

||

|

Equipment warranty |

1 years (standard, above must be charged a certain maintenance cost) for 2 years, 3 years. |

||

|

Heater capacity |

6kw |

15kw |

25kw |

|

Air blower [power (kw), air volume (m /min)] |

nothing |

nothing |

[0.25,9.5] |

|

Draft fan [power (kw), air volume (m /h)] |

[1.5,250] |

[2.2,300] |

[2.2,300] |

|

Compressor [power (kw), air volume (L /min)] |

[0.58,108] |

[1.5,250] |

[1.5,250] |

|

Electric power (installed capacity) |

8kw |

30kw |

40kw |

|

Thermal insulation material |

50mm glass fiber insulated cotton |

50mm glass fiber insulated cotton |

50mm glass fiber insulated cotton |

|

Pulse bag dust collector (optional) |

Polytetrafluoroethylene film mulching material |

||

|

4 |

4 |

9 |

|

|

Shape size (mm) (L x W x H) |

1600×1400×1800 |

2200×1600×2200 |

2600×1200×2500 |

|

Installation weight (Reference) |

500 pounds |

450kg |

1000kg |

|

Power supply |

380V/-3: it can be customized according to different national standards. |

Note 1: water evaporation at inlet temperature of 250 C.

2: for more evaporation equipment, please inquire online or call our company.

Tel: 17317246351

Mailbox: sales@qfn17.com

URL: http://m.iishop.net.cn

Address: Shanghai fengxian canal north road no. 1185